"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

02/08/2016 at 16:08 ē Filed to: None

1

1

17

17

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

"BiTurbo228 - Dr Frankenstein of Spitfires" (biturbo228)

02/08/2016 at 16:08 ē Filed to: None |  1 1

|  17 17 |

Iíve been having issues with my 38mm tubing kinking in my pipe bender, which is not good if youíre looking to make a roll cage.

Figured out why. Itís a _pipe_ bender, not a _tube_ bender, meaning the dies are in BSP sizes, which is some convoluted measurement based on the internal diameter of threads used in plumbing.

So, i looked high and low to find some 42.4mm tubing (bsp 1 1/4") with a 2mm wall to make an insert into my plumbing pipe bender to make it fit 38mm mechanical tube :) the fact that they only sold the tubing in 6.1m lengths so i had to buy that for all of 30cm of tubing is by-the-by...

Iíll test it out tomorrow to see if it works :)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

02/08/2016 at 16:15 |

|

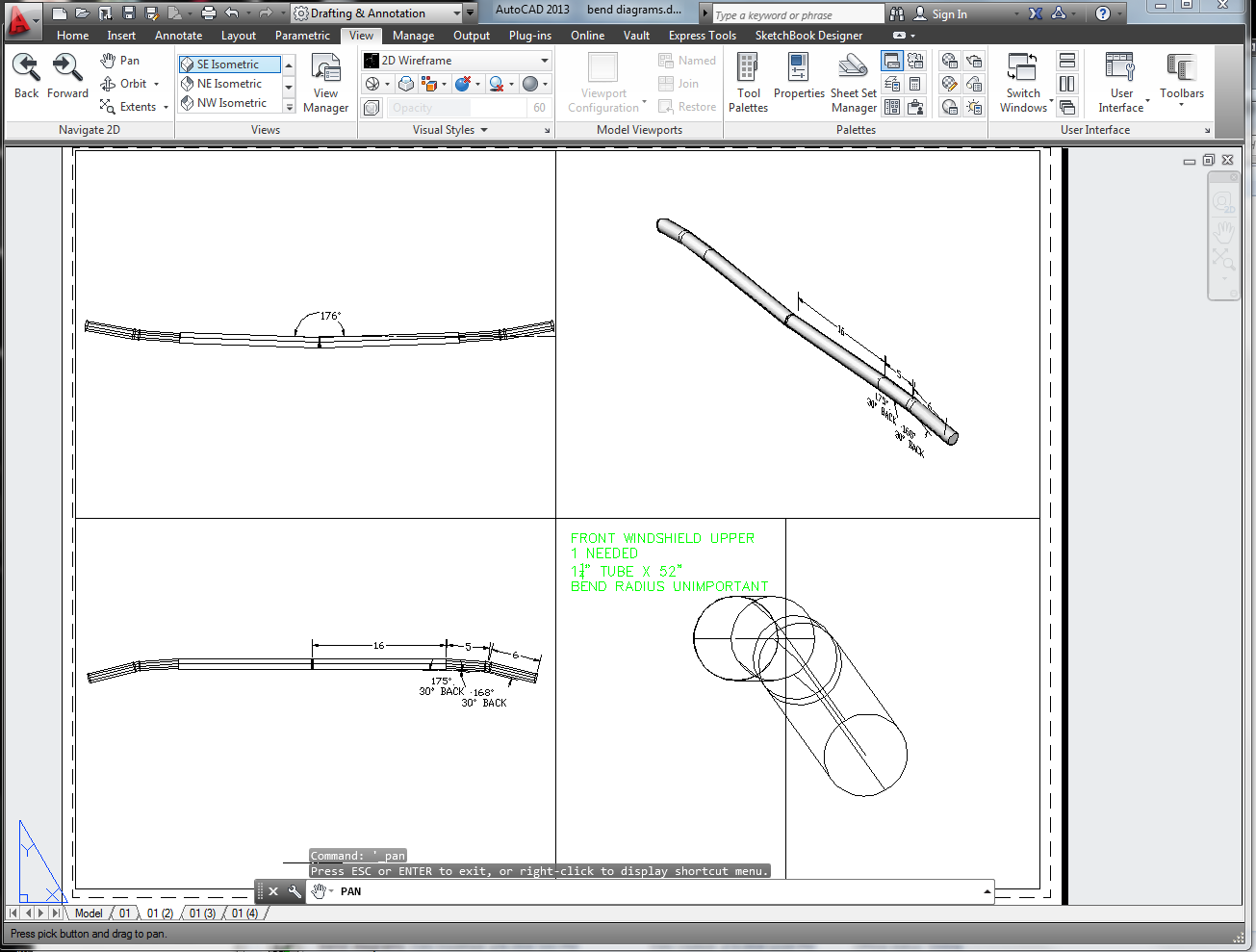

Well done. Iíve been drawing up bits to be bent by a friend of mine with a proper tubing bender, for which he has dies, but a pipe bender made to work properly should do the trick. A sample of what Iíve been up to:

dietryng

> BiTurbo228 - Dr Frankenstein of Spitfires

dietryng

> BiTurbo228 - Dr Frankenstein of Spitfires

02/08/2016 at 16:16 |

|

NIIICE trick.

BiTurbo228 - Dr Frankenstein of Spitfires

> dietryng

BiTurbo228 - Dr Frankenstein of Spitfires

> dietryng

02/08/2016 at 16:35 |

|

Thanks :) weíll see whether it works tomorrow

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

BiTurbo228 - Dr Frankenstein of Spitfires

> RamblinRover Luxury-Yacht

02/08/2016 at 16:38 |

|

Nice :) obviously iíd like a proper tube bender, but theyíre much more expensive.

Yours is going to be semi-invisible isn't it? Very cool :)

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

RamblinRover Luxury-Yacht

> BiTurbo228 - Dr Frankenstein of Spitfires

02/08/2016 at 16:42 |

|

That one there in the pic is the tube Iím going to have under the skin over the windshield. Iíve got a post parallel to the A-pillar on each side that will be visible, but that then goes into a trough thing over the door , and Iíve got a full hoop up the inside of the B-pillars and over the top. Nearly all hidden, but with the A-pillar being smaller than anything else, a bad location at its base, and having curvature, sticking a pipe through it wasnít practical.

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

02/08/2016 at 16:44 |

|

Would a bending spring help? A quick google says they come in 38mm, but maybe not in a heavy enough gauge for your purposes.

Iím only familiar with bending copper pipe, and there the rule of thumb to avoid kinking is a minimum bend radius of around 4x the pipe diameter. If thatís the same with your tubage* then youíre looking at a bend radius of around 150mm - but I suspect thatís to do with the softness of copper, so probably isnít the same.

*Countdown was wrong today, that is a perfectly cromulent word.

dietryng

> BiTurbo228 - Dr Frankenstein of Spitfires

dietryng

> BiTurbo228 - Dr Frankenstein of Spitfires

02/08/2016 at 16:47 |

|

iíve gotten to learn while hanging out with the old ones, that if you cant afford the correct tool, look it over, see how it works, and build your own.

BiTurbo228 - Dr Frankenstein of Spitfires

> dietryng

BiTurbo228 - Dr Frankenstein of Spitfires

> dietryng

02/08/2016 at 17:30 |

|

Yep :) once we've got our garage built properly i'm going to have a go at making a diy flow bench for porting heads :)

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

02/08/2016 at 17:33 |

|

Yeah itís way too tough to be bending without a pipe bender of some sort :S

Would be worth finding out if thatís the same as for steel as that could help as well :)

If i want to make something that would pass MSA inspection then i'll need all the info i can get :)

dietryng

> BiTurbo228 - Dr Frankenstein of Spitfires

dietryng

> BiTurbo228 - Dr Frankenstein of Spitfires

02/08/2016 at 17:39 |

|

ive never had the luxury of a flow bench. usually just clean up the irregularities, and short side radius, blend the bowl, and use a common gasket to guide for overall size. havent hit water yet, and always stayed on the conservative side of cutting. having a way to measure the results most definitely will be effort well spent.

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

02/09/2016 at 09:25 |

|

I was thinking of using the spring with the bender, to try and prevent the tube collapsing.

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

02/09/2016 at 09:32 |

|

Hmmm, if this fails to sort it then Iíll give that a go :)

Someone else suggested packing the tube with sand which is another option

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

02/09/2016 at 09:39 |

|

At what point does it get easier to cut the tube at an angle and weld it back together?

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

02/09/2016 at 10:03 |

|

Right from the get-go, but MSA rules mandate that it has to be one solid length of CDS tube, welded or bolted only when it joins another member.

They even state that it has to be formed using a cold process so no hot sand bending either :S

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

02/09/2016 at 10:07 |

|

I donít quite get what youíre saying. Surely if you have a big bend, if you cut and welded/bolted that would be a separate member?

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

BiTurbo228 - Dr Frankenstein of Spitfires

> davedave1111

02/09/2016 at 10:39 |

|

Basically each loop has to be made from a single unbroken piece of tube. You can weld connecting pieces, and things like backstays onto those loops, but those need to be made up of a single unbroken piece of tube as well.

Basically, when you weld two tubes together end-on it creates a point of weakness that will give way if it's ever properly tested. Not something I'd like to happen in a flimsy little 70s drop-top :S

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

davedave1111

> BiTurbo228 - Dr Frankenstein of Spitfires

02/09/2016 at 11:13 |

|

Oh, I see. Iím used to Ďmemberí being a building term, and there it normally(/always?) means a straight piece.

ďNot something Iíd like to happen in a flimsy little 70s drop-topĒ

Why do you think they call it Ďtop downí motoring? ;)